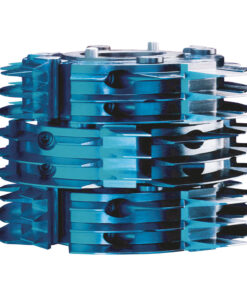

Profile milling cutter Z600

Do you have any questions regarding

Profile milling cutter Z600?

Send us a message! Contact us

Description

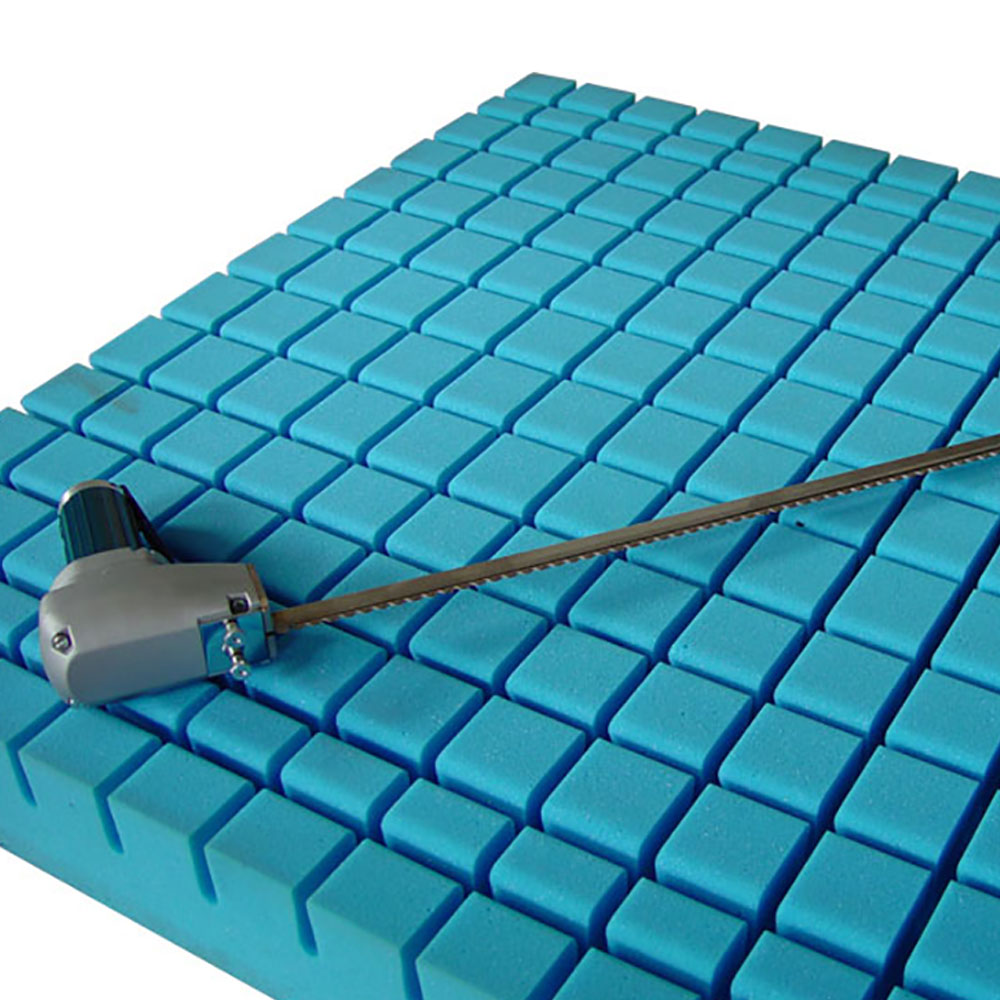

PROFILE MILLING CUTTER Z600

Foam rasp

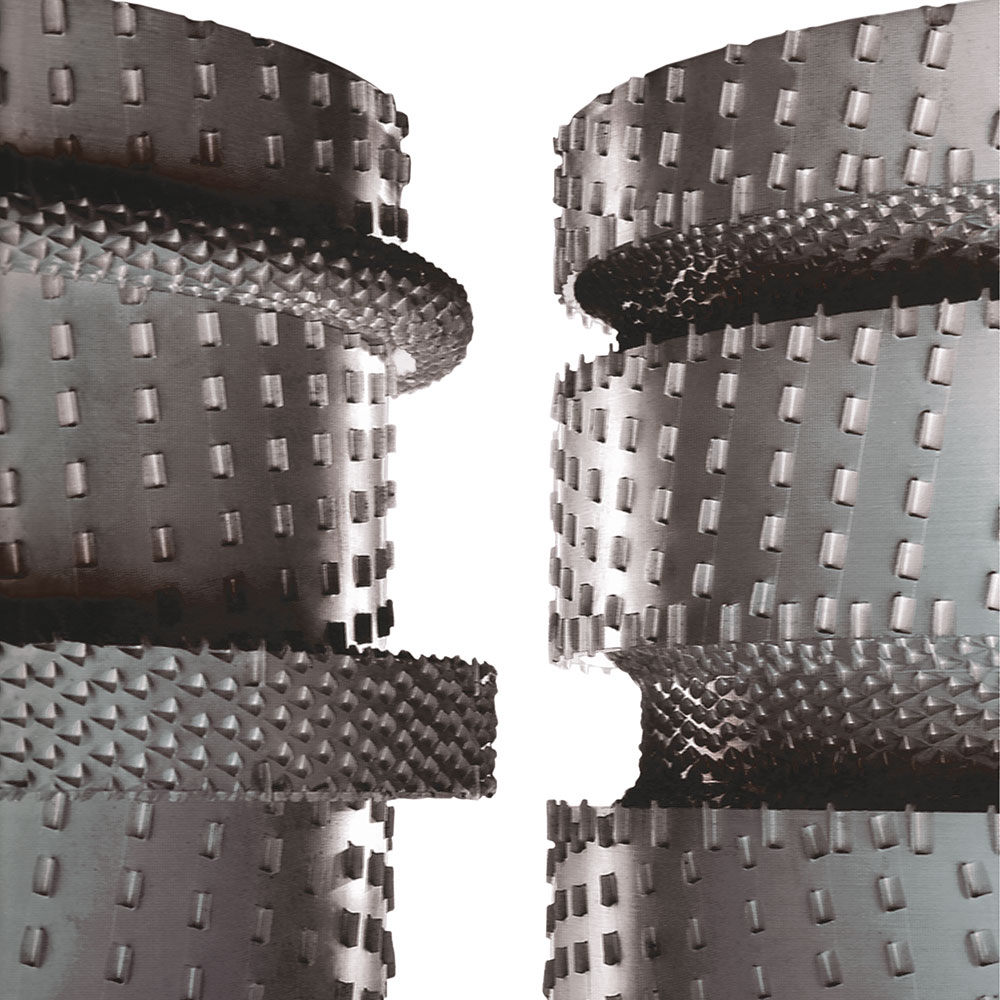

Profile milling cutter with helical blade toothing

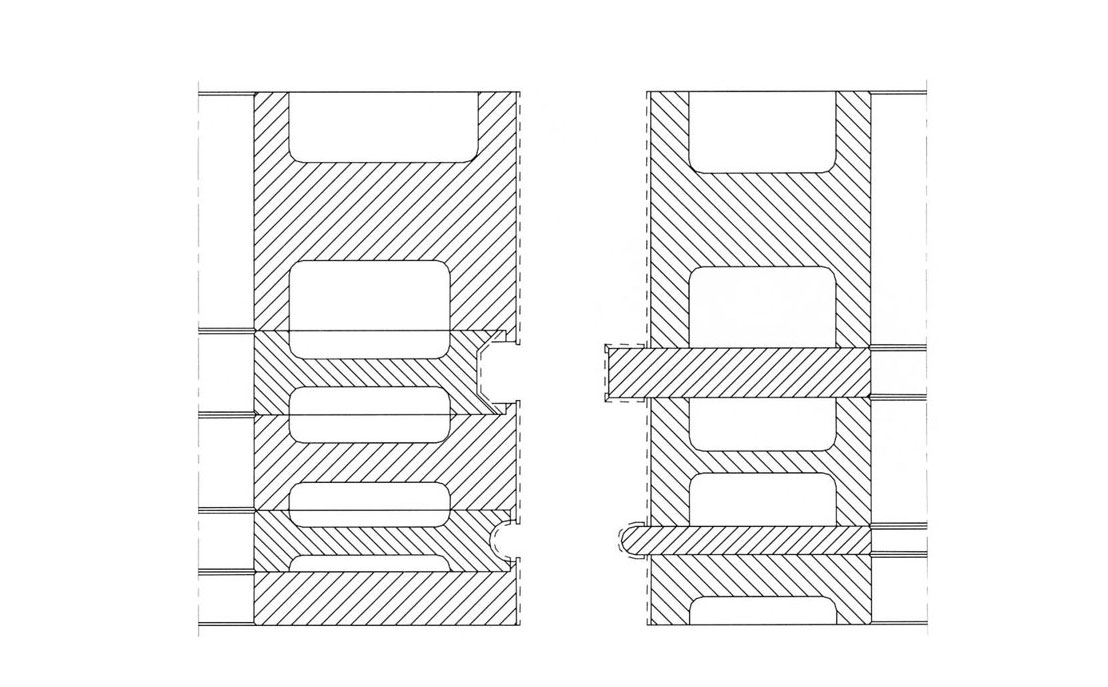

The problem:

Each extruded material has skins on the surface which differ in hardness and thickness depending on the extruder type. These areas are problem areas during milling, which cause the following disadvantages:

– fast tool wear in the “skins” area

– burrs and fraying on the surface layers

The solution:

By inclining a blade-like toothing (instead of the conventional rasp cut), a burr is always drawn into the plate area to be milled. Furthermore, the knife-like cutting edges guarantee a complete overlap from cutting edge to cutting edge and thus lead to a longer service life.

Advantages over carbide milling tools:

– quiet running

– favourable price/performance ratio

– most complicated shapes can be produced as quickly as possible

Contact

Questions about this product? Send us a message!

If you have any questions about this product, you can contact us directly here.

FAQ - Frequently Asked Questions

- Question: Is this inquiry a chargeable order?

- Answer: No, it's a non-binding price inquiry. Zeim Technology provides customized solutions for each customer.

- Question: When can I expect a response?

- Answer: Our customer service usually responds within 24 hours with an individual offer.

Related products

HM-Milling Tools

Rasp Milling Tools

HM-Milling Tools

Rasp Milling Tools

HM-Milling Tools

HM-Milling Tools

HM-Milling Tools

Rasp Milling Tools