Profile cutter Z700

Do you have any questions regarding

Profile cutter Z700?

Send us a message! Contact us

Description

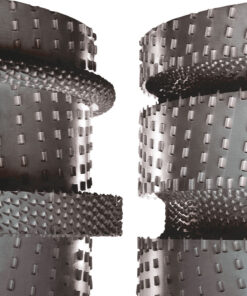

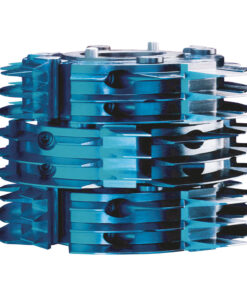

PROFILE CUTTER Z700

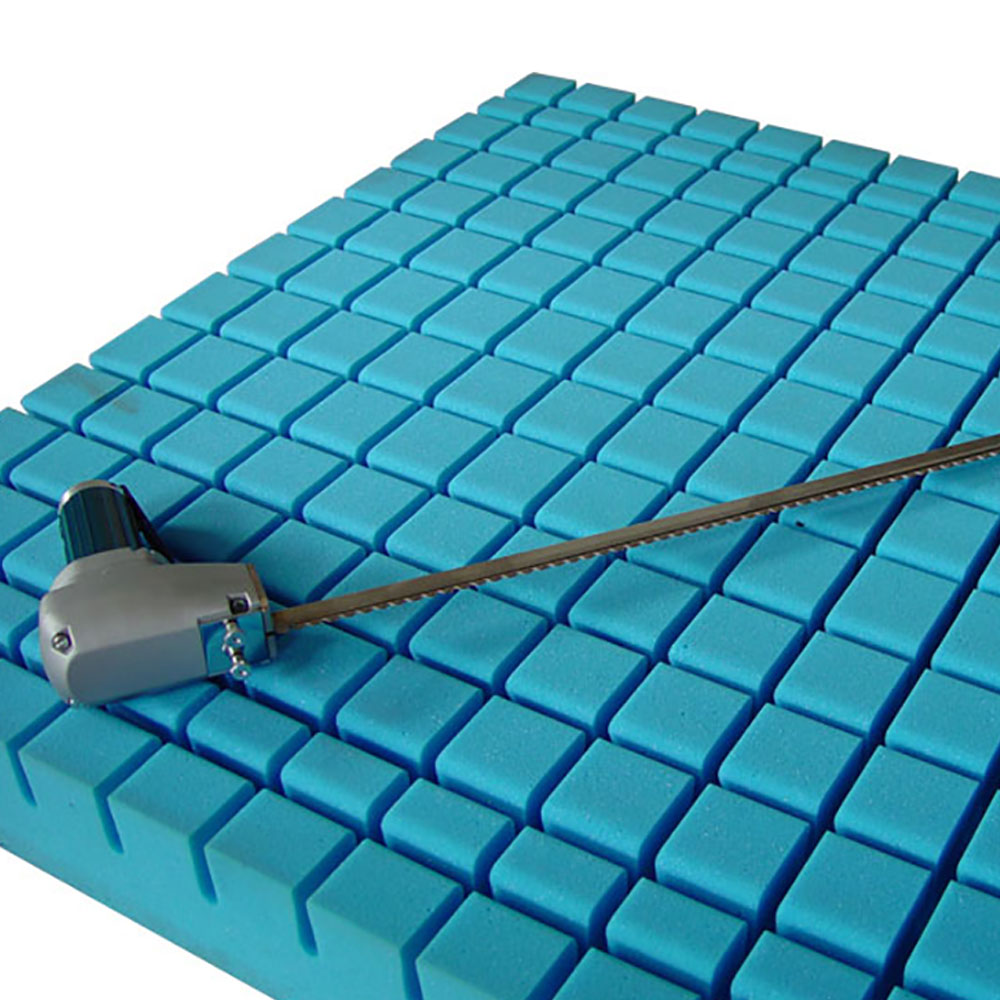

Foam rasp

ZEIM recycling cutter for expanded polystyrene (EPS)

The problem:

Generation of a milling chip suitable for reuse, which avoids clogging of the slotted screens in the block mould. The surface quality shows an acceptable milling pattern.

The solution:

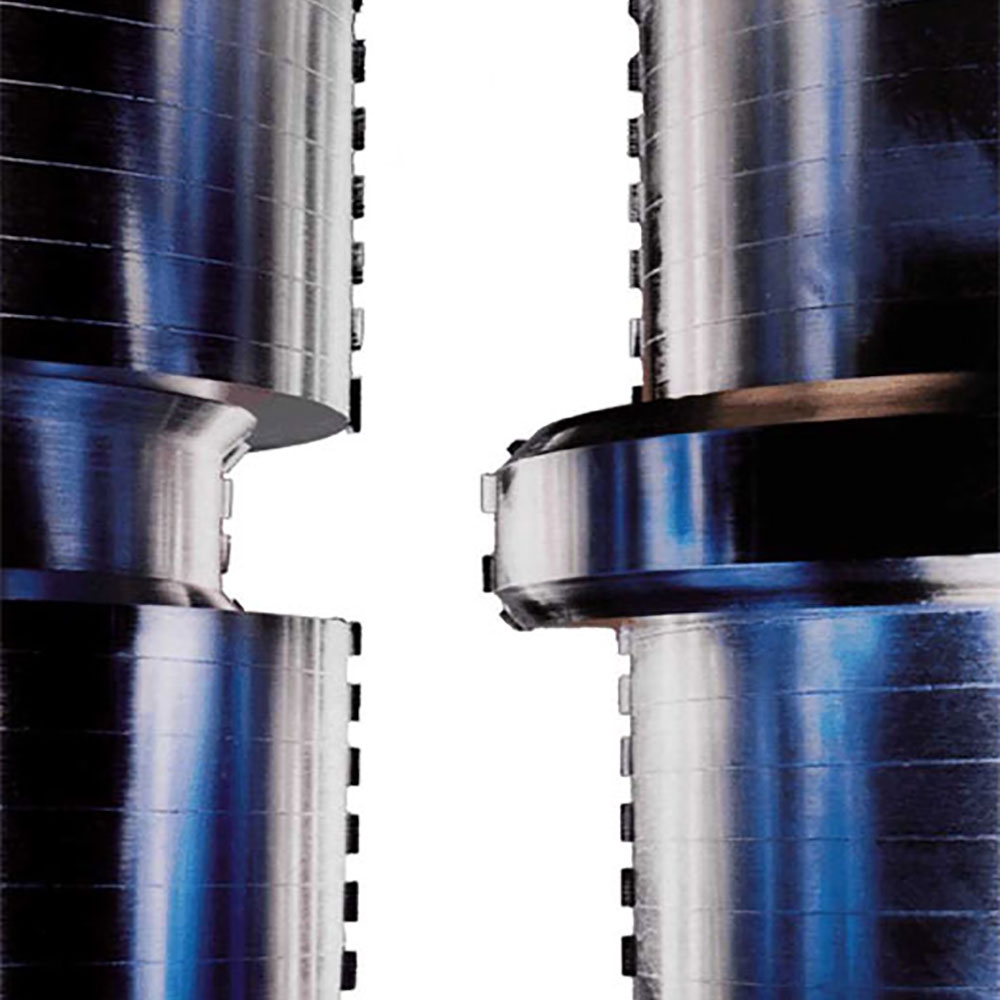

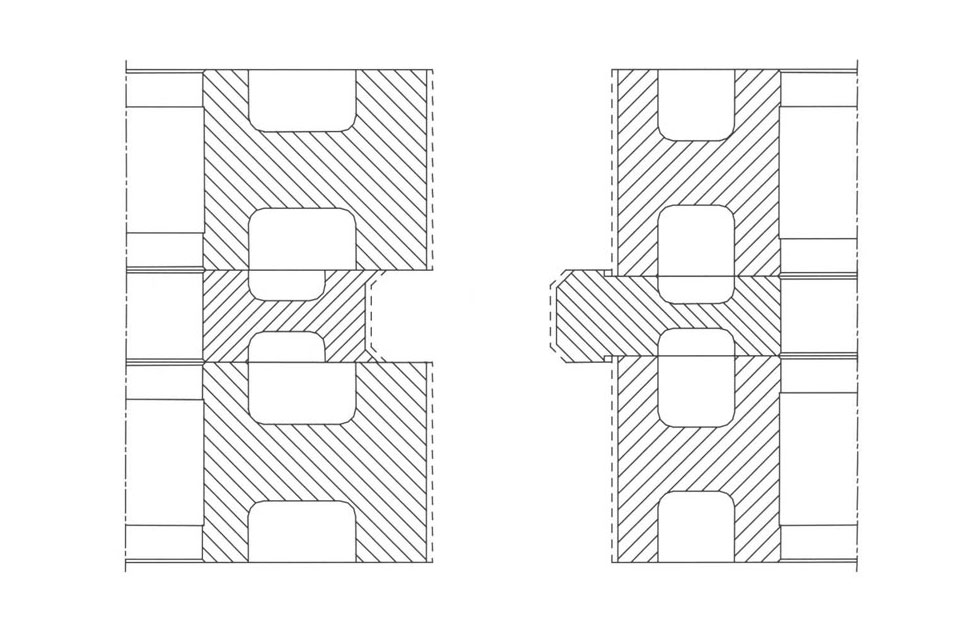

The cutting edge geometries have been fundamentally changed compared to the conventional rasp toothing, i.e. with a small number of cutting edge rows (which nevertheless guarantees sufficient overlapping of the cutting edges), the desired milling grain size is produced with corresponding speed and feed parameters.

Condition:

In order to minimize downtimes (cleaning of the slotted screens) during the production of EPS with reusable milling chips, the use of a dust removal system is absolutely necessary,

– on the one hand to filter the dust generated in the raw granulate or by the shredding machine.

– on the other hand, in order to remove the fine chips which occur to approx. 10% during machining.

Contact

If you have any questions about this product, you can contact us directly here.

- Question: Is this inquiry a chargeable order?

- Answer: No, it's a non-binding price inquiry. Zeim Technology provides customized solutions for each customer.

- Question: When can I expect a response?

- Answer: Our customer service usually responds within 24 hours with an individual offer.

Related products

Rasp Milling Tools

Rasp Milling Tools

HM-Milling Tools

HM-Milling Tools

Rasp Milling Tools

HM-Milling Tools

Rasp Milling Tools